When reading a box maker’s certificate, you’ll often see labels like 200# and 32 ECT. What do these mean, and how do you choose between them? This article will answer these questions.

What The Difference Betweent Mullen Test and Edge Crush Test

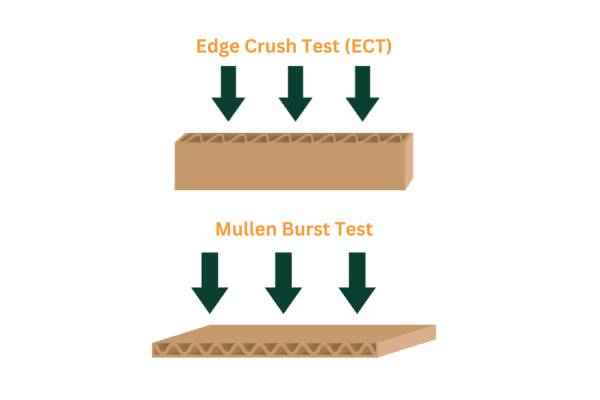

The Mullen Test is used to evaluate the strength of a box. It measures the box’s ability to resist bursting by applying pressure to the outside, with the result given in pounds per square inch (PSI). For example, a rating of 200# means the box can withstand 200 pounds per square inch of pressure without bursting.

The Edge Crush Test (ECT) measures the compressive strength of a piece of cardboard by pressing its edges between two rigid plates and recording the peak load at which it collapses. This result is also given in pounds per inch (lb/in). A 32 ECT rating means the box’s edges can withstand a vertical pressure of 32 pounds per inch before breaking.

While the Mullen Test focuses on a box’s strength to resist impact, the Edge Crush Test focuses on how much weight it can bear when stacked.

Applications of 200# and 32 ECT Boxes

From These two tests are explained above and reviewed in detail, it can be seen that 200# boxes have greater strength.

Therefore, they are often used to transport heavier items like industrial equipment and mechanical parts. During long-distance shipping, these things can make a great impact on the box. As a result, a strong box is needed for safe transport of those we wish to keep around. Another major use of 200# boxes is to transport fragile items such as glass this time again with the high strength box reduces impacts during transportation helping hold item intact.

On the other hand, 32 ECT boxes are for lighter goods that is least likely to be damaged during shipping. These boxes are lighter than 200# boxes, making it even more economical, which is good news for businesses.

What Should You Consider When Choosing Between 200# and 32 ECT Boxes?

To make a decision between 200# and 32 ECT boxes it is important to take factors into account. Here is a detailed breakdown of each aspect.

Product Weight

For heavier products to be shipped, the best choice is 200# box. Otherwise there could be damage in transit, which might harm items inside.

Shipping Condition

When long-distance shipping or harsh transportation conditions are involved, 200# boxes are the top choice due to their higher strength. In contrast, 32 ECT boxes are better suited for standard shipping conditions.

Product Sensitivity

Some products need special protection on their long road to market-and any injury at all could ruin them. In cases such as these, use 200# boxes for superior protection.

Box Weight

200# boxes are heavier, so the shipping cost to transport the same weight of goods will be higher than 32 ECT type boxes.

Cost Considerations

The cost of producing a 200# box is higher than that of 32 ECT boxes, so if the items being transported are not particularly heavy and do not require any special protection, transportation conditions are moderate then use 32 ECT boxes to keep distribution costs down.

Environmental Impact

200# boxes are heavier than 32 ECT boxes, meaning they require more materials to produce. Although both types of boxes are recyclable, 32 ECT boxes are more eco-friendly from a resource-saving perspective.

Conclusion

After reviewing the information provided above you should be able to make a choice, between 200# and 32 ECT boxes. ReanPackaging is a packaging specialist and will provide you with profesional shipping boxes wholesale service. Welcome to reach out to us if you have any questions, about our packaging boxes.