Adhesive Tape is widely used in daily life due to its practicality. So, what do you need to know about adhesive tape? Perhaps reading this article will be sufficient. Let’s get started!

What is Adhesive Tape

Adhesive tape is a material used to stick objects together on their surfaces. It typically comes in a flexible strip with one side being sticky and the other side non-sticky. By applying pressure to the non-sticky side, the tape adheres to the surface. Because of this characteristic, adhesive tape is commonly used to bond, protect, or bundle objects.

How Adhesive Tape Works

Adhesive tape is typically composed of a backing material and a transparent adhesive applied to the backing. When pressure is applied to the tape, it adheres to surfaces of different materials. This structure allows it to perform various functions, such as connecting two objects or wrapping and enclosing items. Additionally, different backing materials and adhesives can impart additional functionalities to the tape, which will be explained in detail later in the content.

What is The Material of Adhesive Tape?

In the previous section, we mentioned that adhesive tape is composed of a backing material and transparent adhesive. Now, let’s delve into the materials that make up the backing and adhesive.

Materials Constituting the Backing

Depending on the intended use of the adhesive tape, the backing material can vary.

Polyethylene

Polyethylene is a commonly used plastic and the most frequent material for tape backing. The backing made from this material is often used for transparent tape and packing tape.

Polyvinyl Chloride (PVC)

Polyvinyl chloride is another material used in tape backing. It is known for its durability and is often employed in the production of insulating tape and other tapes with high durability requirements.

Fabric

Materials such as cotton, polyester, and fiberglass are used to make tape backing. Fabric-backed tape is known for its strength, resistance to breaking and wearing, making it suitable for reinforced tape.

Paper

Tape with paper backing has lower strength and is more prone to tearing, but it offers the advantage of being easily writable. This type of tape, made with paper backing, is lightweight and is often used for light sealing, labeling, and similar tasks.

Polyester Film

Tape backing made from polyester film provides good transparency and insulation. Consequently, this type of tape is commonly used in electrical equipment.

Polyimide Film

Tape backing made from polyimide film has excellent heat resistance and corrosion resistance, making it suitable for extreme environments such as high temperatures. It is typically used in the production of welding tape.

Polypropylene

Polypropylene-backed tape is corrosion-resistant and moisture-resistant. This type of tape is well-suited for protecting items in special environments, such as petroleum pipelines and natural gas pipelines.

Aluminum Foil

Tape backing made from aluminum foil is heat-resistant, has good fire resistance, and seals excellently. This type of tape is commonly used in the production of refrigerators and air conditioners.

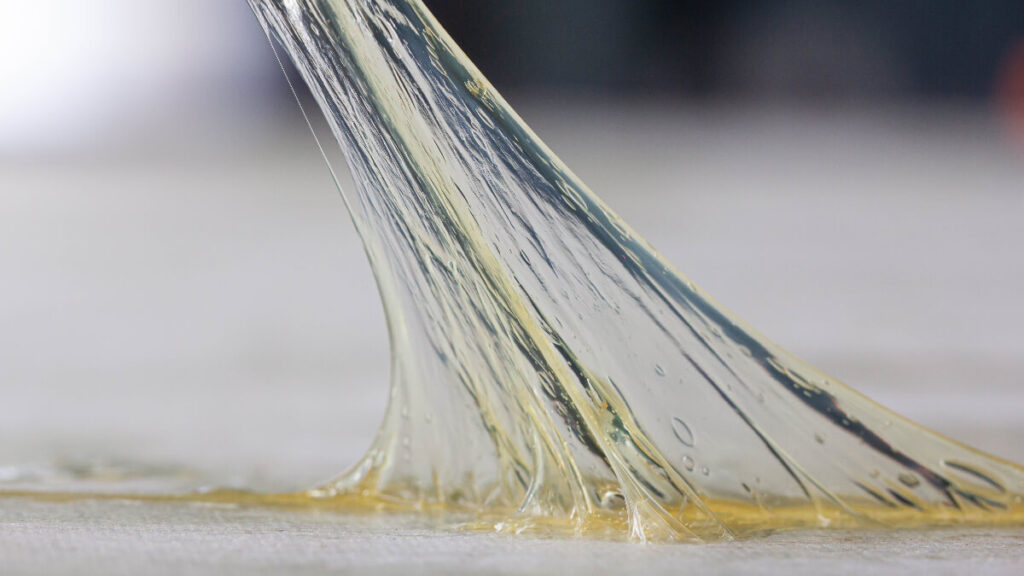

Adhesive Materials

Similar to tape backing, there are various materials available for the adhesive of tape to meet different purposes.

Rubber-Based Adhesive

Rubber-based adhesive was one of the first adhesives used in tapes. It has strong adhesion, and most commonly used transparent tapes in our daily lives are made with this material.

Acrylic-Based Adhesive

Acrylic-based adhesive is a pressure-sensitive adhesive. It adheres to the surface of an object with just a slight pressure and is often used in transparent tapes or medical tapes.

Acrylic Ester-Based Adhesive

This adhesive is a variation of acrylic-based adhesive with stronger adhesion and water resistance. It remains effective even in humid conditions.

Silicone-Based Adhesive

Silicone-based adhesive has excellent heat resistance and is commonly used for making insulating tape.

Water-Based Adhesive

Some tapes use water-based adhesive, which does not contain environmentally harmful organic solvents and does not emit harmful gases, making it environmentally friendly. This type of adhesive is often used in the production of medical tapes.

Chemical Reaction Adhesive

Some specialty tapes require the use of adhesives based on chemical reactions, such as epoxy resin, polyurethane, phenolic resin, and others.

How is Adhesive Tape Made?

The process of adhesive tape production involves several steps: coating, drying, cutting, winding, and packaging. Now, let’s take a closer look at each of these processes.

Step 1: Coating

In this process, the backing material passes through a coating machine where an adhesive is applied onto it through coating rollers. The crucial aspect here is ensuring the precise thickness and uniformity of the adhesive, as it directly impacts the quality of the resulting tape.

Step 2: Drying

The main purpose of drying is to solidify the adhesive on the backing material. After the coating process, the backing material enters an oven, and the temperature and duration of drying vary depending on the adhesive material.

Step 3: Cutting

The tape, now dried, goes through a cutting machine to be cut into the desired length and width.

Step 4: Winding

The cut tape enters a winding machine, where it is rolled into a cylindrical shape. This completes the production of the tape ready for our use.

Step 5: Packaging

The finished tape is packaged according to transportation requirements.

Types of Adhesive Tape

Masking Tape

Masking tape, also known as painter’s tape, leaves no residue on surfaces after use. It is convenient because it can be torn by hand without the need for scissors or other tools when you need a specific length. Painters particularly favor masking tape; they use it to mask areas they don’t want to paint and often employ it to secure canvases. Hence, it’s also referred to as painter’s tape.

Electrical Tape

Electrical tape exhibits excellent insulation properties, effectively preventing electrical leakage. It is commonly used in electrical engineering for maintenance and repairs.

Double-Sided Tape

Double-sided tape has adhesive on both sides, allowing it to bond two surfaces together. It is frequently used in crafting and other manual tasks.

Packaging Tape

Packaging tape is typically wider than other tapes and possesses strong adhesive properties. A gentle press is sufficient to firmly attach it to surfaces, making it widely used in product packaging.

Medical Tape

Medical tape directly contacts the skin, requiring unique properties. It must be breathable, have moderate adhesiveness (to avoid pain when removed), and use safe, non-toxic materials to prioritize patient safety.

Transparent Tape

Transparent tape is widely used in daily life, such as sealing envelopes and repairing torn paper.

Adhesive Bandage Tape

Compared to medical tape, adhesive bandage tape is wider and has stronger adhesion. It is commonly used in first aid and surgical procedures for effective fixation.

Reflective Tape

Reflective tape has excellent reflective properties, quickly catching attention in darker environments. It is often used as a warning in low-light conditions, like on the rear of trucks to alert following vehicles.

Anti-Slip Tape

Anti-slip tape, with a rough surface and high friction, effectively prevents slipping. It is commonly applied in places prone to accidents, such as stairs and ramps.

Waterproof Tape

Waterproof tape maintains good adhesion even in damp environments, making it ideal for protecting surfaces in wet conditions.

Double-Sided Foam Tape

Double-sided foam tape offers strong adhesion, even on rough surfaces, and its foam material allows it to absorb vibrations effectively. It finds widespread applications in furniture and automotive manufacturing.

Paper Tape

Paper tape allows easy drawing and writing on its backing, and compared to other tapes, it can be effortlessly torn by hand without the need for scissors. It is commonly used in crafts, artwork, or as label paper.

Tamper Evident Tape

Tamper-evident tape leaves a mark if removed, making it ideal for securing important documents during transit, ensuring they remain unopened.

High-Temperature Tape

High-temperature tape, as the name suggests, is designed to function in high-temperature environments, typically ranging from 120 to 260 degrees Celsius. It is often used in processes like painting and leather finishing, where temperatures are elevated.

Carpet Tape

Carpet tape is frequently used for exhibitions and hotels to secure carpets. It boasts strong adhesion and is resistant to water and oil.

Weather Stripping Tape

Designed for outdoor use, weatherstripping tape provides excellent waterproofing and UV resistance. It withstands prolonged sunlight exposure without deformation, making it effective for sealing doors and windows in extreme conditions.

Gaffer Tape

Gaffer tape, widely used in the entertainment industry, is primarily employed to secure cables on the floor to prevent tripping hazards.

Drywall Tape

Drywall tape is typically used in conjunction with joint compound to connect and repair joints between gypsum boards. It is commonly applied in home renovations and construction projects.

How Are Adhesive Tapes Applied?

The use of adhesive tape generally depends on its specific characteristics, but there are still some general guidelines that we can follow.

Surface Preparation

When using tape, unless it’s designed for specific purposes, ensure that the contact surface is clean and dry. Moisture, dust, grease, and other contaminants can affect the tape’s adhesive properties.

Choose the Right Tape

As discussed in the previous section, there are various types of tapes with different characteristics. Choosing the appropriate tape for your specific purpose can significantly enhance its effectiveness.

Avoid Overstretching

When applying tape, try to avoid overstretching to prevent the tape from losing its elasticity, which can impact its performance.

Read the Instructions

Some tapes come with instructions for use. It’s essential to carefully read these instructions before application to ensure optimal tape performance.

How To Choose the Right Tape

Step 1: Choose the Tape Type

As detailed earlier, the first step is to select the appropriate type of tape based on your specific needs.

Step 2: Select the Right Length and Width

Once you’ve identified the type of tape, the next step is to determine the suitable length and width. This depends on the application, and standard options are usually available. However, if these don’t meet your requirements, customization is an option.

Step 3: Read the Tape Specifications

For specialized tapes, it’s crucial to delve into the specifications. Let’s look at some essential parameters in the specification sheet:

Thickness: Thickness is closely related to the tape’s strength and durability. Thicker tapes are not necessarily better; excessively thick tapes may lack flexibility and struggle with curved surfaces.

Adhesive Strength: This indicates how strongly the tape adheres to a surface, typically measured in inches per ounce. A higher value implies stronger adhesive strength.

Tensile Strength: The force required to break the tape, usually measured in pounds per inch.

Elongation: Related to tensile strength, it measures how much the tape can stretch when subjected to force. A higher elongation rate indicates better elasticity.

Temperature: Specifies the range of temperatures at which the tape performs optimally. High temperatures can affect the tape’s adhesiveness.

Step 4: Consider the Price

Once you’ve determined the type and performance characteristics of the tape, it’s time to consider the price. Typically, aim for the lowest-priced option that meets your quality requirements.

Conclusion

After reading the above content, I believe you now have a comprehensive understanding of adhesive tape. At ReanPackaging, you can find various types of adhesive tapes that suit your needs. If you have any questions about purchasing or using adhesive tape, feel free to contact us.

FAQ

What Conditions Make Tape Fail?

Several conditions can lead to tape failure:

Contaminated Contact Surface: Dust, moisture, or grease on the contact surface of the tape can adversely affect its performance.

Extreme Temperatures: Some tapes may experience performance issues in extremely high or low temperatures.

Prolonged Exposure to UV Radiation: Extended exposure to ultraviolet (UV) radiation can cause a decline in adhesive properties for certain tapes.

Humidity Impact: Extended exposure to high humidity can cause tapes to absorb moisture, affecting their performance.

Expiration: Tapes have a shelf life, and using them beyond their expiration date can inevitably result in reduced adhesive strength.

Chemical Exposure: Certain chemicals can impact tape performance. Accidental contact with these chemicals may lead to a loss of adhesive strength or other issues.

Mechanical Damage: Scratches or cuts on the surface of the tape can compromise its adhesive properties.

How To Test Tape?

There are various dimensions to test when it comes to tape. Below are some items to test and the corresponding testing methods:

Tensile Strength Test: Tensile strength is a critical performance aspect of tape. It is typically tested by placing the tape in a tensile testing machine to measure its resistance to stretching.

Peel Strength Test: Peel strength, or the force required to peel the tape from a surface, can be measured using a peel strength tester. This test assesses the tape’s adhesion capabilities.

Viscosity Test: The viscosity of the adhesive in the tape can be tested using a viscosity meter, providing insights into the adhesive’s performance.

Temperature Resistance Test: Expose the tape to high temperatures to test its performance under elevated temperature conditions.

UV Exposure Test: Expose the tape to ultraviolet (UV) light using a UV lamp to assess its resistance to UV radiation, evaluating its suitability for outdoor applications.

Electrical Performance Test: For insulating tapes, testing electrical insulation properties may involve methods like voltage breakdown tests to ensure suitability for electrical applications.

Environmental Testing: In specific applications, environmental performance testing may be necessary. This could include evaluating whether the adhesive is harmful or if the backing material is biodegradable.

Why Tape Is Better Than Glue?

In some situations, people prefer using tape over glue for several reasons:

Convenience: Tape is more convenient as it provides an instant bond without the need for drying time. Unlike glue, which requires some time to solidify and achieve adhesion, tape allows for immediate use, reducing waiting time.

Versatility: Tape has a broader range of applications because it has lower requirements for the material of the contact surface. In contrast, glue may not be suitable for certain specific surfaces.

Portability: Tape is often available in rolls, making it compact and easy to store and carry. This portability is advantageous, especially in situations where on-the-go solutions are needed.

Flexibility: Tape is often used for temporary bonding, making it easy to tear or peel off. In contrast, objects bonded with glue are usually more challenging to separate once the glue has cured.

What is The Best Way to Store Adhesive Tape?

In the previous discussion, we talked about the conditions that can cause adhesive tape to lose its effectiveness. When storing adhesive tape, it’s crucial to avoid environments that can compromise its performance.

Avoid Extreme Temperatures: Adhesive tape should be stored away from both excessively high and low temperatures, as extreme temperatures can impact its performance.

Moisture Control: Prevent prolonged exposure to humidity by avoiding storage in damp environments.

Vertical Storage: Whenever possible, store adhesive tape vertically. This minimizes the tape’s contact area with the surface, reducing the potential impact of continuous pressure on its performance.

Pressure Avoidance: Do not place heavy objects on top of the tape to prevent deformation under pressure.

Chemical Separation: Store adhesive tape away from chemicals to avoid potential interactions that may lead to a decrease in adhesive strength.

Maintain Dry Conditions: Ensure that the storage location for adhesive tape is well-ventilated and remains dry.

Shield from Direct Sunlight: Prolonged exposure to direct sunlight can cause the tape to fade or even result in a loss of adhesive strength. Store tape away from direct sunlight.

Regular Inspection: Periodically inspect the tape for any visible damage or deformation on the surface.

Follow Manufacturer’s Recommendations: For certain types of adhesive tape, manufacturers may provide specific usage instructions. Adhering to their guidelines ensures the proper and scientifically sound storage of the tape.

Tips On Adhesive Tape Removal

Sometimes, when we peel off adhesive tape, there may be some residue left on the surface of the tape and the object. So, how do we remove these residues? The following methods might be worth trying:

Heat: Use hot water or a hairdryer to wipe the surface. This softens the adhesive, making it easier to remove.

Oil-based Substances: Some adhesives can dissolve in oil-based substances. Wiping the surface with olive oil or vegetable oil can help remove adhesive residues.

Soapy Water: Using soapy water operates on a similar principle to using oil-based substances. It dissolves the adhesive in the soapy water.

Blade or Knife: Gently scrape the contact surface with a blade to remove the residual adhesive, but be cautious not to scratch the surface.

Freezing: Place the tape in the freezer; the adhesive’s stickiness may weaken in a low-temperature environment. Then, gently scrape it off with a blade.

Adhesive Remover: You can purchase specialized adhesive removers. Follow the product instructions for effective removal of adhesive residues.

More Resources:

Adhesive Tape – Source: Wikipedia

Adhesive Tape Introduction – Source: IQS Directory

What is Adhesive Tape – Source: Quora