Cardboard and corrugated cardboard are common materials we use to make packaging boxes. They often get confused because they look and serve somewhat similarly. So, what are the differences between cardboard and corrugated cardboard, and how can we distinguish them? This article aims to provide a clear answer to these questions and help you overcome any confusion.

Definition

Cardboard is a general term for heavy paper-based products. It includes thin cardstock used for items like business cards and postcards, as well as thicker single-layer cardboard suitable for packaging materials. Even corrugated cardboard is a type of cardboard. However, in the packaging industry, the term “cardboard” is commonly used to refer to the thicker single-layer cardboard. In this article, we focus on this type of cardboard.

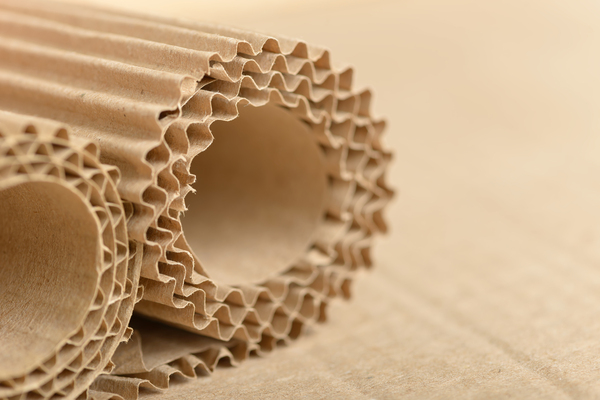

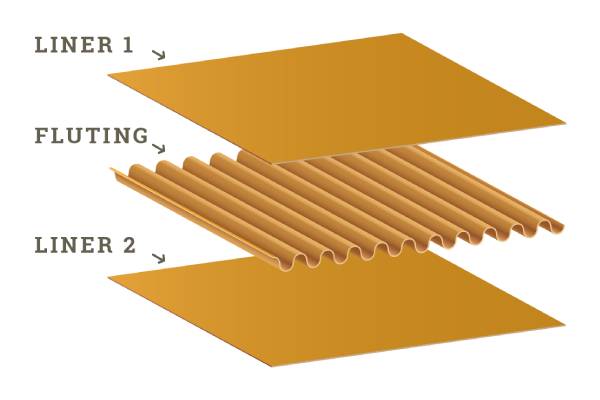

Corrugated cardboard gets its name from its structure. It typically refers to cardboard that consists of two layers of single-layer cardboard with a corrugated or wavy layer sandwiched in between. Corrugated cardboard has various specific classifications, which we will discuss in the following sections.

Materials & Structure

Cardboard employs a single-layer structure, deriving its considerable hardness primarily from the texture of the pulp. The pulp fibers used to produce cardboard have a high density and relatively long length compared to those used in the production of other paper products. This high fiber density and length are key to ensuring that the produced cardboard possesses strong hardness and strength. After being produced through the pulping process, the cardboard undergoes heating and drying. During this process, the cardboard solidifies, further enhancing its hardness.

The corrugated cardboard we commonly encounter consists of three layers – two layers of paper on top and bottom, with an intermediate layer of corrugated medium. In this structure, the corrugated medium, bent between the two layers of paper, forms numerous voids in the vertical direction between the layers of cardboard. This enables the cardboard to evenly distribute forces, thereby enhancing overall strength and making it less prone to damage. Additionally, the wave-like structure of corrugated cardboard effectively absorbs and slows down impacts, providing better protection for items inside the packaging. In terms of materials, corrugated cardboard doesn’t demand as high-quality pulp as cardboard. The pulp used for corrugated cardboard is often made from more affordable materials like recycled paper.

Strength and Durability

Regular cardboard is relatively thin, lightweight, and not as sturdy as corrugated cardboard. It is suitable for light packaging. Corrugated cardboard, on the other hand, is thicker and possesses strong impact resistance, making it superior in terms of strength and durability. It is well-suited for transporting heavier items, providing more effective protection during the shipping process. Additionally, corrugated cardboard can be categorized based on the number of layers – single-walled, double-walled, triple-walled. The more layers of corrugation, the greater the strength, enabling it to bear heavier loads.

However, everything has its pros and cons. The high strength of corrugated cardboard is attributed to its structure and thickness, but this also means it has a greater weight. When transporting items, the weight of the packaging is a crucial factor in calculating shipping costs. If the packaging itself is too heavy, it can increase transportation expenses.

Design & Printing

The surface of cardboard is relatively smooth, allowing for high-quality printing. Advanced techniques such as hot stamping and embossing can be applied to enhance the surface. In contrast, the surface of corrugated cardboard is rough, resulting in lower print resolution. Many surface treatment processes are also impractical on corrugated cardboard. Therefore, compared to corrugated cardboard, cardboard provides businesses with more space to unleash their creativity. This is advantageous for them to use packaging as a means to convey their brand image.

Applications

Given the distinct characteristics described above, cardboard and corrugated cardboard have different applications. When transporting relatively light items, packaging made of cardboard will be a more cost-effective choice. Common examples of such packaging include gift boxes and e-commerce shipping boxes. However, when dealing with heavier items or requiring long-distance transportation, packaging made of corrugated cardboard should be your preferred option. Common examples of this type of packaging include shipping boxes and moving boxes. In addition to the weight of the items being transported, there are other factors to consider when choosing between cardboard and corrugated cardboard as packaging materials:

- Whether the packaging requires careful design: If you have high design requirements for packaging, you should consider cardboard packaging.

- Whether the items are fragile: If the items being transported are fragile, it’s advisable to use packaging made of corrugated cardboard. Its excellent cushioning performance provides better protection for fragile items.

Environmental Impact

Both cardboard and corrugated cardboard are recyclable, and they can quickly degrade into carbon dioxide and water in the natural environment, causing no pollution. However, concerning packaging reusability, corrugated cardboard has a higher level of reusability. As mentioned earlier, packaging made of cardboard can be intricate and often suitable for specific occasions, making it less suitable for reuse in many cases. On the other hand, corrugated cardboard is commonly used to make corrugated boxes. As long as the corrugated box is not severely damaged, it can be reused to carry heavy items. Additionally, corrugated boxes are easy to disassemble and assemble. When not in use, they can be quickly folded flat, occupying minimal space for convenient storage. These characteristics allow a corrugated box to be reused multiple times, contributing to resource conservation.

Cost of Use

Corrugated cardboard is composed of three layers – two layers of paper on top and bottom, with an intermediate layer of corrugated medium. The bonding of the paper layers and corrugated medium requires the use of glue, making the materials used in corrugated cardboard more extensive compared to single-layer cardboard. Consequently, the cost incurred is higher. Additionally, due to the more intricate structure of corrugated cardboard, its production process is more complex, resulting in higher costs than cardboard. As mentioned earlier, the transportation costs for corrugated cardboard are higher than for cardboard. Considering all these factors, the overall cost of using corrugated cardboard is higher than that of cardboard.

Conclusion

Cardboard and corrugated cardboard each have their own advantages, and their utility can be maximized when applied in suitable contexts. We hope this article helps you in choosing packaging made of cardboard or corrugated cardboard. If you have any further questions, feel free to contact us at Reanpackaging. If you need to purchase packaging supplies made of cardboard or corrugated cardboard, you can browse our website and request a quote.

More Resources:

What Are The Differences Between Corrugated And Cardboard? – Source: Quora

Corrugated Fiberboard– Source: Wikipedia

Types of Cardboard and Corrugated Boxes – Source: Thomasnet