Product packaging is a container created for the purpose of enclosing and showcasing a product. It serves to provide proper protection for the product during transportation, storage, sales, and other processes. Simultaneously, brand owners can utilize the design of the packaging to communicate their brand image.

Why Packaging Design Is Important

Effective packaging design plays a crucial role in product packaging, and here are specific reasons why:

Capture Customer Attention: Before customers interact with the product, they first encounter the packaging. A good packaging design can instantly grab the attention of potential customers, leaving them with a positive first impression.

Enhance Brand Awareness: Through the packaging design process, you can seamlessly integrate your brand image. This results in increased exposure throughout the product’s lifecycle, making it more memorable and gaining an edge in competition with rivals.

Marketing Tool: Packaging itself serves as a marketing tool. When two similar products are on a shelf, with similar brand recognition and pricing, customers may choose a product with distinctive packaging, making it stand out.

Provide a Positive User Experience: The process of opening the packaging is a crucial element in building a positive user experience. Factors such as ease of opening, functional design, and distinctive appearance all impact customers’ overall evaluation of the product.

Create Differentiation: In industries where products are highly homogeneous, effective packaging design can differentiate your product from others. By creating uniqueness, you can attract customers and gain an advantage in the competitive market.

Protect Merchandise: The primary function of packaging is to protect the product. Optimal protection can be achieved through careful selection of packaging materials and thoughtful design of the packaging shape and features.

What Your Should Do Before Starting the Design

To create the perfect packaging, you need a thorough understanding of your brand, product, and target customers. Only then can your packaging design achieve optimal effectiveness.

Understand Your Brand

What is Your Brand Philosophy and Positioning?

The brand philosophy plays a crucial guiding role in packaging design. For instance, Nike’s philosophy is “Just Do It.” To align with this philosophy, Nike’s packaging design is dynamic, using concise yet bold colors to inspire individuals to pursue their goals and unleash their potential. Similarly, when designing your packaging, it’s essential to align with your brand philosophy to reinforce brand recognition among customers.

In addition to the brand philosophy, brand positioning is another crucial factor influencing packaging design. If your brand is positioned as high-end, opt for premium materials in packaging. Consider using techniques like foiling and embossing on the packaging surface. In terms of colors, gold and silver are recommended for a more glossy appearance, aligning with a luxurious brand positioning.

As illustrated in the example above, brand philosophy and positioning impact the choice and application of elements like materials, colors, and fonts in packaging design. Therefore, understanding them is the first thing you need to do before embarking on packaging design.

Understand Your Product

Types of Products

Different products have varied packaging requirements. Food products often demand packaging with good sealing and insurance capabilities. Electronic products like smartphones require packaging that provides sufficient protection against impacts or static damage. Design the packaging according to the type of product to ensure better protection.

Product Characteristics

A good packaging design should make it convenient for customers to use and store the product. To achieve this, understanding the characteristics of the product is crucial. Taking laundry detergent packaging as an example, many laundry detergents use plastic bottles with a handle and a pouring spout at the bottle’s mouth. Customers can easily grip the plastic bottle handle to pour out the detergent through the spout. Additionally, the detergent’s cap has a scale, allowing customers to measure the amount of detergent used. After use, sealing the detergent becomes easy by closing the cap. This design considers the liquid nature and weight of the detergent. Without a handle, controlling the pouring speed of liquid is challenging. The pouring spout effectively prevents dripping during liquid pouring. Moreover, knowing the amount of detergent used is inconvenient, so the cap is equipped with a measuring cup. Lastly, as liquids require sealed storage, the detergent uses a screw cap to provide reliable sealing and prevent leakage. Only by understanding the product’s characteristics and carefully considering the issues customers may encounter during use can we design packaging that customers will love.

Product Appearance

Product appearance encompasses size, shape, and colors used. Packaging often needs to closely fit the product’s surface to provide ample protection. Therefore, the product’s size and shape often determine the packaging size. Regarding colors, the packaging color generally needs to match or complement the product’s color, using the same or adjacent/complementary colors.

Where the Product Is Displayed

The display channel for a product affects packaging requirements. If your product is showcased on shelves in offline supermarkets or convenience stores, your packaging design needs to be more eye-catching, as your product is often displayed alongside competitors. Brighter colors and more appealing patterns can quickly grab customers’ attention and influence their purchase decisions. If your product is displayed at a counter, the packaging design needs to emphasize the brand, focus more on the packaging’s texture, and be compatible with the counter’s display space. If your product is sold online, consider the packaging’s display effect on the screen. In such cases, clear images, concise design, and recognizable elements are preferred to ensure customers can easily see the packaging details even on the screen.

Understand Your Target Audience

Who Are Your Users?

Identifying your users is a crucial factor to constantly consider in packaging design. For instance, if your target customers are children, you can incorporate cute animal images and bright colors in the packaging design. On the other hand, if your customers are professionals, the design style may lean towards simplicity and business aesthetics, emphasizing a professional image. Depending on customers’ age, occupation, and status, it’s essential to consider their preferences and habits in designing the packaging.

What Matters to Them When Purchasing Products

After identifying your customers, understanding what matters to them when making a purchase is equally important. For example, if mothers are buying products for their babies, their primary concern might be safety. In this case, the packaging design should highlight the safety of the product. Elements like green leaves can symbolize safe and non-toxic materials, while a shield element can represent thorough inspections in the production process. Additionally, using soft colors like light blue or light green can evoke a sense of reassurance for customers.

Conceptualizing Packaging

What Are the Functions of Packaging?

In some cases, packaging requires additional functional design. For example, when consuming nuts, one might not finish them in one go. In such situations, a nut bag with resealable functionality is beneficial, allowing customers to seal the bag after consumption, thus extending the freshness of the nuts. Consider whether your product needs functional design and what type of functionality is required before formally starting the packaging design.

Choosing the Type of Packaging

Packaging can be categorized into various types based on form. Choose the suitable packaging type for your needs:

Boxes

- Common packaging made from sturdy materials like cardboard.

- Available in different sizes and shapes.

- Applicable to various product categories, including food and electronics.

Bags

- Important packaging type, including plastic, paper, and cloth bags.

- More convenient to carry with one hand compared to boxes.

Cans

- Typically cylindrical containers made of metal or plastic.

- Excellent sealing properties, suitable for products with high sealing requirements, such as food, beverages, and paint.

Bottles

- Usually made of glass or plastic.

- Used for liquid products like essential oils and beverages.

Drums

- Cylindrical containers with good sealing properties.

- Used for storing relatively heavy liquids or powders, such as paint.

Tubes

- Generally made of plastic or metal.

- Used for containing substances like creams or gels; squeezing the tube dispenses the product, suitable for items like toothpaste and creams.

Designing Packaging Systems

A complete packaging system comprises outer packaging, inner packaging, and product packaging. Outer packaging typically refers to the protective layer on the outside, often in the form of a box or bag. Inner packaging refers to the filler material between the outer packaging and the product, often composed of thin paper or foam to prevent the product from being squeezed or impacted. Product packaging is the direct packaging that comes into contact with the product, such as bottles for beverages or bags for bread.

In many cases, you may not need to design all components of the entire packaging system. However, if needed, you should have an integrated design for outer packaging, inner packaging, and product packaging. This involves considerations such as coordinating colors among the three, planning the size proportions, and other aspects.

Competitor Research

After the above-mentioned tasks, it is crucial to conduct research on competitors. This is important because our ultimate goal is for the packaging to help our product stand out in the competition. Therefore, understanding the strengths and weaknesses of competitors’ packaging designs is essential to find an appropriate strategy to surpass them. There are various methods for conducting research. For instance, we can visit physical stores to observe which products have the best designs and highest sales. On e-commerce platforms, we can examine the packaging displays of competing products, focusing on user reviews to identify comments about the product packaging and find potential areas for improvement. Additionally, exploring unboxing videos by influencers on platforms like YouTube can provide valuable insights into the competitor’s packaging. Finally, summarize the collected information about the strengths and weaknesses of competitor packaging from various channels, identifying aspects to learn from and areas where improvements can be made.

Budget

Another crucial aspect to focus on before packaging design is the budget. While we may strive for perfection in design, the reality is that budgets are often limited. For example, a boss may set a requirement that the cost of producing each package should not exceed $0.5. In such cases, the options for material selection and processing techniques may be constrained, requiring adjustments to the initial design concept to align with the packaging budget.

Design Your Packaging Step By Step

After completing the preparatory work mentioned above, we can finally commence the packaging design process. The packaging design can generally be broken down into the following steps:

Confirming Materials, Shape, and Size of the Packaging

The choice of materials is determined by the packaging type and budget constraints. Generally, a higher budget allows for the use of better materials. The shape and size of the packaging depend on the dimensions of the product. Packaging manufacturers typically provide reference dimensions for efficiency and cost-effectiveness during production. Using these dimensions ensures lower production costs, as they don’t have to make individual adjustments for each processing step based on your specific requirements.

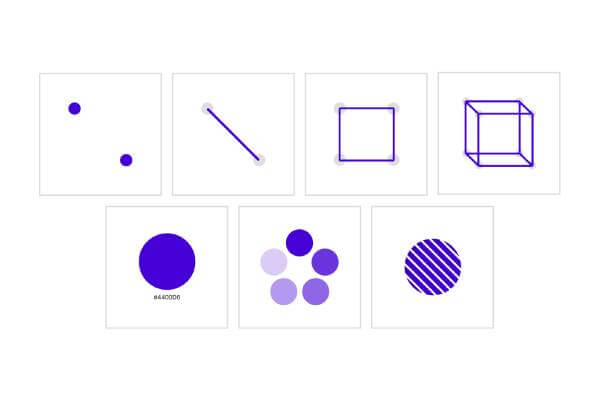

Design Elements

Design elements encompass color, fonts, packaging copy, graphics, and more. These elements need to be decided based on brand identity, product characteristics, customer preferences, and other factors. We have previously provided detailed descriptions of how these factors influence design elements. Combining these design elements results in a comprehensive visual design concept. Typically, multiple versions of the design are created, and team members review and compare different designs to arrive at the final visual design concept.

Generating 3D Models

Next, our creative concepts are implemented in 3D software. In the software, we can obtain a realistic representation of the product packaging, observing how it appears from different angles, under various lighting conditions, and in different settings.

Packaging Evaluation

Before entering the formal production phase, it’s essential to evaluate our packaging design. We assess whether the 3D model generated in the software aligns with our expectations for the packaging design. This evaluation helps identify any details that may have been overlooked and require adjustments before moving into the formal production stage. These adjustments can be made within the software.

Design Production Files

After the packaging design has been evaluated, we need to create the production files for packaging printing.

Organizing Design Files

This involves gathering all essential elements, including images, text, dimensions, colors, and other relevant information.

File Size and Resolution

Ensure that the file size matches the actual dimensions of the final packaging and set a sufficient resolution to guarantee print quality.

Adding Trim and Bleed Areas

For packaging design, it’s common to add trim and bleed areas. The trim area represents the actual edges of the final packaging, while the bleed area is a small extension beyond the trim area to ensure no white edges are left during printing.

Color Mode

Common color modes include RGB and CMYK. For printing, CMYK is typically chosen because it closely resembles the true colors of printing inks, resulting in minimal color deviation in the printed output.

Exporting in Production File Formats

When exporting the generated files, choose appropriate file formats such as PDF, AI, EPS, etc. Ensure that the selected format is supported by the production equipment.

Confirming Printing Type

Before the formal production phase, it’s crucial to confirm the printing type, usually choosing between digital printing and offset printing. Digital printing involves transferring images directly from computer files to printing devices using digital technology, eliminating the need for plates. It allows for quick adjustments and production but is costlier, making it suitable for small batch printing. Offset printing transfers ink from an image on a plate to a printing surface and then onto paper, requiring plate-making. This method is often used for large-scale printing, providing efficiency and cost-effectiveness. Choose the appropriate printing type based on the required delivery time and budget constraints for the packaging.

Print Samples For Final Confirmation

Before entering mass production, it’s essential to print samples for a final confirmation. The key aspects to verify include:

Color Accuracy

Ensure that the colors in the printed samples match those in the design files. Check for any color deviations or distortions.

Printing Quality

Thoroughly inspect the printing quality, examining the clarity of images and text. Look for issues such as missing prints, overprints, or blurring.

Size and Positioning

Verify the accuracy of the size and positioning of the printed samples. Check for any trimming discrepancies, scaling problems, or misplacements.

Printing Materials and Surface Treatment

Examine the printing materials used to ensure they meet specifications and requirements. Also, confirm whether the correct surface treatments (such as coating, lamination, etc.) have been applied.

Color Separation and Adjustments

For multicolor printing, check the accuracy of each color separation. Confirm whether the interaction and overlay of colors meet the design expectations.

Finishing and Post-Processing Effects

If subsequent processing or post-processing is required for the printed products (such as lamination, foil stamping, UV coating, etc.), ensure that these effects align with the design requirements and are flawless.

Once all the above aspects have been thoroughly checked and verified, the packaging design work can be considered complete, and you can proceed with the formal mass production of the packaging.

Commonly Used Packaging Design Software

Several commonly used software tools for packaging design include:

Adobe Illustrator

Adobe Illustrator, commonly known as AI, is a vector graphics editing software. It is frequently used to create graphic elements, logos, and patterns for packaging design. With rich illustration and layout tools, it supports both print and digital media design, making it a staple tool in packaging design.

Adobe Photoshop

Adobe Photoshop, often referred to as PS, is a raster graphics editing software. It is utilized for processing and editing photos, images, and textures in packaging design.

CorelDRAW

CorelDRAW is another vector graphics design software, competing with Adobe Illustrator. Both are effective tools for packaging design; however, designers may have different preferences based on their habits and workflows.

Rhino (Rhinoceros)

Rhino is a 3D modeling software commonly used for product modeling and rendering in packaging design. It is useful for visualizing the final effect of packaging production before actual manufacturing.

SketchUp

SketchUp is an easy-to-use 3D modeling software suitable for quick sketches and conceptual design in packaging. It allows designers to rapidly present concrete visualizations of their ideas in the packaging design process.

Gathering Inspiration for Packaging Design

To consistently create exceptional packaging designs, it’s essential to collect examples of outstanding packaging designs for inspiration. Here are some ways you can try:

Follow Design-Oriented Social Media Platforms

Stay tuned to packaging designers on social networking sites like Behance, Dribbble, and Pinterest. Explore their latest packaging design works and save those that stand out to you.

Observe Product Displays

Pay attention to the products on store shelves when you go shopping, particularly focusing on the packaging designs of different brands. Analyze how they attract customers’ attention on the shelves.

Attend Design Exhibitions

If there are high-quality packaging design exhibitions, consider attending them. Engage with other designers, share experiences and perspectives, and stay updated on the latest trends in the packaging design industry.

Document Your Findings

Most importantly, organize the examples you collect into a folder. Summarize and categorize them for a better understanding. This folder will become your treasure trove of inspiration for future packaging designs, enabling you to create eye-catching designs quickly.

Trends in Packaging Design

While the packaging design for each product varies, there have been common trends in packaging design development over the past few years.

Sustainability and Environmental Friendliness

With the increasing awareness of environmental issues among consumers, there is a growing emphasis on sustainability in packaging design. The use of eco-friendly materials and the incorporation of biodegradable materials are becoming crucial trends in packaging design to minimize waste.

Simplicity and Clarity

Consumers are gradually becoming weary of flashy packaging. In the future, straightforward and simple packaging designs may be welcomed, allowing consumers to quickly access information and understand the product’s features and highlights.

Cultural Diversity and Inclusivity

The world has become a global village, with people from different countries and ethnic backgrounds living together. Packaging designs that embrace cultural diversity and inclusivity can appeal to a broader audience. This inclusivity is recognized as a future trend in packaging design.

Conclusion

In this article, we provided a comprehensive introduction to packaging design. We hope that after reading this article, you have a better understanding of what packaging design entails and how to achieve an effective design. Of course, there are many aspects of packaging design that we couldn’t cover in one article. If you have any questions about packaging design, feel free to contact us through the website. ReanPackaging‘s experienced packaging designers will promptly respond to your inquiries.

More Resources:

Packaging Design: A Practitioner’s Manual – Source: Google Books

Packaging Design: Successful Product Branding From Concept to Shelf – Source: Google Books