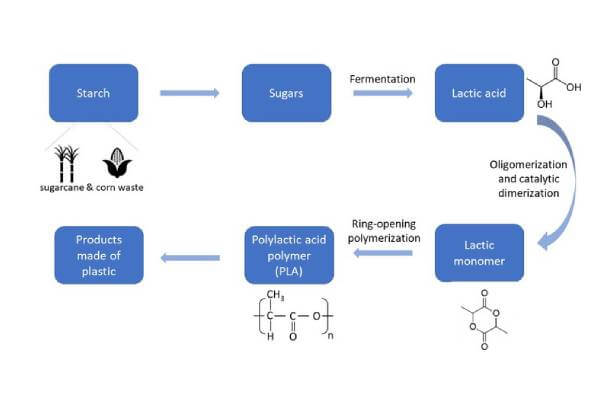

PLA is the abbreviation for Polylactic Acid, a type of biodegradable plastic. It is typically synthesized through artificial chemical processes using plant materials such as corn starch. PLA exhibits excellent biocompatibility and biodegradability.

How PLA Is Made?

The production of PLA typically involves the following steps:

Raw Material Extraction

PLA is derived from sugars found in plants. The first step is to extract sugars from plants, often utilizing materials such as corn starch and sucrose. These materials are chosen because of their high sugar content, and corn and sugarcane have wide cultivation areas with high yields, making them cost-effective raw materials.

Hydrolysis

Starch and sucrose are polysaccharides. To use them as raw materials for PLA production, they need to be hydrolyzed into glucose with the help of enzymes.

Fermentation

The hydrolyzed glucose, in the right environment, undergoes bacterial action, typically by lactic acid bacteria. This process converts glucose into lactic acid.

Lactic Acid Polymerization

Lactic acid undergoes polymerization to form polylactic acid (PLA). This process involves condensation reactions where lactic acid molecules link together to form long chains, ultimately creating the polymer PLA.

Pellet Formation

The PLA polymer is processed into pellets, which serve as raw materials for manufacturing various products.

What Are The Types of PLA?

Polylactic acid (PLA) can be categorized into different types based on its chemical structure:

PLLA (Poly-L-Lactic Acid)

PLLA is the most common form of PLA. It has a higher melting point and high crystallinity. It is often used in scenarios that demand high strength and rigidity, such as the production of medical implants and sutures.

PDLA (Poly-D-Lactic Acid)

In contrast to PLLA, PDLA has a lower melting point and lower crystallinity. It is rarely used alone but is often mixed with PLLA to adjust the material’s properties, enhancing PLLA’s performance, such as improving flexibility.

PDLLA (Poly-DL-Lactic Acid)

PDLLA is a mixture composed of both PLLA and PDLA. The combination results in varying degrees of changes in the material’s mechanical strength, crystallinity, biodegradability, etc. This versatility allows PLA to find widespread applications in different fields, including packaging, biomedical applications, 3D printing, and more.

PLA Properties

High Stiffness

PLA is a material known for its high stiffness, making it suitable for various structural applications. It is ideal for manufacturing lightweight yet strong components.

Low Melting Point

PLA has a low melting point, making it highly processable. Its ability to melt at lower temperatures makes it a popular choice for injection molding and 3D printing.

Good Aesthetic Properties

PLA exhibits good transparency and gloss, resulting in aesthetically pleasing products when used as a raw material. Additionally, its texture is smoother than many other plastics, making it suitable for crafting decorative items.

Low UV and Temperature Resistance

PLA has relatively poor resistance to UV rays and high temperatures. Therefore, this material is not suitable for prolonged exposure to sunlight or high-temperature environments. It’s crucial to consider this aspect when using products made from PLA.

Chemical Resistance

PLA has good resistance to typical acidic and alkaline substances (such as hydrochloric acid, sulfuric acid, sodium hydroxide, etc.). However, stability may vary in different chemical environments, so it’s advisable to follow the manufacturer’s recommendations when using or storing PLA-made products.

Dimensional Stability

PLA maintains dimensional stability during the manufacturing and usage processes, minimizing significant deformations.

Crystallinity

As a semi-crystalline polymer, PLA’s crystallinity influences its physical properties. Higher crystallinity generally implies increased strength and hardness.

Strength

PLA exhibits high strength, making it suitable for a wide range of applications, including prototyping and structural components.

Advantages of PLA

Renewable Resource

PLA is a renewable resource because its main raw materials come from plants. In contrast to conventional plastics, which are derived from petroleum, PLA’s use of plant-based materials makes it more environmentally friendly, reducing waste of natural resources.

Low Carbon Emissions

The production process of PLA does not rely on fossil fuels, resulting in fewer carbon emissions during manufacturing and reducing the carbon footprint.

Biodegradability

PLA can naturally degrade in the right environment, without producing harmful substances to the environment. It does not persist in soil or seawater, preventing soil pollution or harm to marine life.

Non-toxic

The production of PLA typically doesn’t require the use of toxic additives or catalysts. Therefore, PLA is non-toxic and does not emit harmful gases during its application in areas such as medical equipment or video packaging.

Disadvantages of PLA

Higher Cost

Compared to regular plastics, PLA has higher raw material costs and a more complex production process, resulting in higher production and usage costs.

Low Heat Stability

PLA has lower heat stability, typically around 150-160 degrees Celsius. This means that under high-temperature conditions, PLA may become soft and lose shape stability. Therefore, it is not suitable for use in high-temperature environments or applications requiring heat resistance.

Brittleness

PLA exhibits relative brittleness, especially at low temperatures. This makes it potentially less durable in some applications compared to other plastics, particularly in cold weather conditions.

Biodegradation Speed

Although PLA can degrade, its degradation speed in actual environments is influenced by various factors, including temperature, humidity, and the presence of microorganisms. In some environments, the degradation speed of PLA may be relatively slow, leading to potential environmental residue.

Difficulty in Recycling

Despite being a biodegradable material, during the actual recycling process, PLA is challenging to separate when mixed with other plastics. This difficulty makes the recycling of PLA materials complicated.

Application of PLA

Food Packaging

The non-toxic and biodegradable nature of PLA makes it an ideal choice for food packaging. PLA material can be used to create disposable cups, bowls, and other utensils.

Cosmetic Packaging

PLA, with its excellent transparency, glossiness, and moldability, is well-suited for cosmetic packaging applications.

3D Printing

Due to its low melting point, ease of processing, and non-toxic nature, PLA is widely used in the field of 3D printing. It doesn’t emit toxic gases when heated, making it a popular choice.

Textile Industry

Fibers made from PLA can be used in the textile industry to produce bio-based fabrics. Utilizing this material helps reduce reliance on traditional synthetic fibers and decreases the demand for petroleum.

Medical Devices

With its biocompatibility, biodegradability, and versatility, PLA is used in the manufacturing of medical implants and devices. Applications include orthopedic implants, sutures, and scaffolds.

Prototyping

Due to its ease of processing, cost-effectiveness, and excellent performance in 3D printing, PLA is commonly used in prototyping. Producing prototypes through 3D printing with PLA can effectively reduce trial-and-error costs before moving on to mass production of certain products.

Final Disposal Methods for PLA

Recycling

PLA materials can be recycled, and the recycled PLA can be used to manufacture new PLA materials, reducing the demand for raw materials.

Composting

In an industrial composting environment, PLA materials can decompose into water and carbon dioxide, leaving no harmful residues.

Incineration

PLA materials can also be processed through incineration. The by-products of PLA incineration are water and carbon dioxide, making it environmentally benign. However, the incineration process should take place in specialized incineration facilities.

Landfill

Landfill is not the most ideal disposal method for PLA. In traditional landfills, where there is a lack of oxygen and suitable humidity, PLA may not effectively decompose, leading to its accumulation in the soil.

Future of PLA

The future development of PLA holds many promising directions.

Enhancing Biodegradability

One of the primary reasons for using PLA materials is their environmental friendliness. However, there is significant room for improvement in PLA’s biodegradability. In the future, advancements in PLA’s molecular structure and the addition of biodegradation enhancers could enhance its overall biodegradability.

Improving Heat Stability and Toughness

PLA currently exhibits relatively low heat stability and toughness. Future advancements can involve employing new production processes and using novel additives to enhance PLA’s heat stability and toughness. This would broaden its applications across various industries.

Enhancing Recycling Methods

The current recycling of PLA is challenging, mainly because it is difficult to distinguish from common plastics during the recycling process. Future improvements in recycling processes and methods can aid in reducing the demand for PLA raw materials, thereby increasing resource efficiency.

Reducing Production Costs

The current production cost of PLA is relatively high. As more factories engage in PLA production, technological innovations are expected to bring about cost reductions, enhancing PLA’s competitiveness.

Increasing Diversity of Bio-Based Raw Materials

The current raw materials for PLA production are relatively limited, with corn starch being the most commonly used. This raises concerns about the impact on corn as a crucial food supply. In the future, efforts to produce PLA from a broader variety of plants in a cost-effective manner could address this issue effectively.

Conclusion

In the face of an increasingly environmentally conscious consumer base, PLA (Polylactic Acid) is finding ever-expanding applications. Understanding PLA is crucial for making informed choices when purchasing products made from this material. We hope that, after reading this article, you will have a comprehensive understanding of PLA. If you have any further questions about PLA, feel free to reach out to us through Reanpackaging. We would be delighted to provide answers. If you’re looking to procure packaging made from PLA, you can search for PLA on our product page. We will promptly get in touch with you upon receiving your inquiry.

FAQ

Strategies to Enhance PLA Properties

Plasticization

The use of suitable plasticizers can enhance the flexibility and processability of PLA. Common plasticizers include plasticizing agents and toughening agents. Plasticizing agents improve the plasticity of PLA, reduce its glass transition temperature, thereby enhancing flexibility. Toughening agents increase PLA’s toughness, making it more impact-resistant and slowing down crack propagation.

Mineral Fillers

Introducing mineral fillers such as nanoparticles and fibers can increase PLA’s hardness, strength, and wear resistance. Mineral fillers enhance PLA’s structure at the molecular level, improving its mechanical properties.

Impact Modifiers

Incorporating impact modifiers like modified polymers or elastomers can enhance PLA’s impact resistance. Impact modifiers absorb impact energy, preventing crack propagation and improving PLA’s impact resistance.

Polymer Blending

Blending PLA with other suitable polymers allows for the adjustment of various properties, such as improving thermal stability and enhancing mechanical performance.

Is PLA plastic The Right Choice For My Brand?

Yes, in today’s consumer landscape, environmental consciousness is a growing concern. Choosing PLA as an eco-friendly material is favored by consumers, enhancing your brand’s image as socially responsible. This decision communicates to consumers that your brand is committed to environmental responsibility.

Is It Safe To Use PLA Products In A Microwave Oven?

In most cases, it is safe to use PLA products in a microwave oven. However, it is essential to consider the specific PLA product and follow the manufacturer’s guidelines for usage. Some PLA products may feature a specific microwave symbol, indicating their suitability for microwave use. Always check for this symbol to ensure safe usage.

Why Is PLA Also Known As “Corn Plastic”?

PLA is commonly referred to as “Corn Plastic” because one of its primary raw materials is extracted from corn starch.

What Are The Alternatives To PLA?

There are several alternatives that can replace PLA, each having its own advantages and disadvantages in specific applications and performance requirements. Here are some common alternatives to PLA:

Polyethylene

Types: High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), etc.

Features: Polyethylene is a common petroleum-based plastic with good chemical resistance, abrasion resistance, and electrical insulation. However, it lacks the biodegradability feature of PLA.

Polypropylene

Features: Polypropylene is another common plastic with a higher melting point and tensile strength. It is less biodegradable compared to PLA but may be more suitable for specific applications.

Polyvinyl Chloride (PVC)

Features: PVC is a versatile plastic widely used in construction, medical, and packaging industries. However, the production and disposal of PVC may involve the release of toxic gases, raising environmental and health concerns.

Bioplastics

Types: Besides PLA, there are other bioplastics such as Polyethylene Furanoate (PEF), Polyhydroxyalkanoates (PHA), etc.

Features: These plastics are usually partially or entirely based on biomass, offering renewable and biodegradable characteristics. They can serve as alternatives to PLA in certain applications.

Polyester

Types: Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), etc.

Features: PET is widely used for bottled beverages, while PBT is common in electronic and automotive components. These plastics exhibit good properties in terms of malleability and mechanical performance but generally lack the biodegradability of PLA.

Polyetheretherketone (PEEK)

Features: PEEK is a high-performance engineering plastic with excellent heat resistance, chemical stability, and mechanical properties. It is suitable for demanding industrial applications but lacks the biodegradability of PLA.

Starch-Based Plastics

Features: These plastics are typically a mixture of starch and other polymers, offering biodegradability. However, their performance may be affected by sensitivity to humidity and poor heat resistance.

More Resources:

Polylactic acid – Source: wikipedia

WHAT IS PLA? – Source:twi-global