Wholesale Large Gift Boxes

Are You Searching For Wholesale Large Gift Boxes? Our bulk packaging solutions combine durability, style, and affordability, which are ideal for celebrating special moments for brands of any kind!

Explore Our Large Gift Box Collection Now

At the intersection of practicality and presentation lies our wholesale large gift boxes. Crafted from top materials like rigid cardboard, eco-friendly kraft paper, and luxury-coated stock, each box provides visual impact and structural integrity for lasting use in corporate gifting, subscription services, retail packaging, or special event presentations. Precise manufacturing with reinforced corners, seamless edges, and consistent color reproduction across orders of any size ensure brand fidelity across orders regardless of order size – these versatile containers allow ample room for product arranging or set packaging while offering space for product arranging arrangements or set packaging as part of an experience brand experience!

Companies trust our boxes because of their stackability, storage efficiency, and protective qualities which help keep contents secure during shipping and handling. With minimum order quantities starting at 500 units and volume discounts for larger requirements available to businesses of any size. With customization options starting from only 500 pieces each order.

Customization Solutions Available

Customizable Product Elements

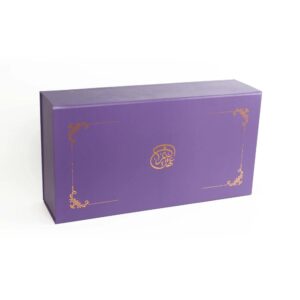

Flexibility is key when creating the ideal packaging solution for your brand, so our wholesale large gift boxes can be fully tailored to match your exact specifications and brand requirements. Choose between sizes ranging from standard 10″x10″x5″ up to 20″x16″x6″, with telescope lids, magnetic closures, fold-flat construction, or window cutouts to showcase contents, not to mention surface finishes including matte to high gloss laminates with soft touch laminate finishes like linen or silk surfaces for surfaces to highlight contents. You’re guaranteed an exact match every time! Both spot printing options and process printing options available from manufacturers ensure complete customization!

Brand elements can be included through techniques including foil stamping in gold, silver, or holographic finishes; embossing for tactile logos; embossing or debossing to achieve tactile logos; embossing for tactile logos; spot UV coating to accentuate high contrast details; ribbon handles that match your palette color scheme and interior customization such as foam inserts, tissue wrapping dividers or platform risers to provide memorable unboxing experiences, each element can be transformed to form packaging that works as powerful extensions of your brand identity!

Minimum Order Quantity Required

Understanding order requirements helps you plan effectively for your packaging needs. Our standard Minimum Order Quantity (MOQ) for wholesale large gift boxes starts at 500 units for most standard designs to keep the cost-efficient for small to midsize businesses and startups and may increase to 1,000 for highly customized custom boxes requiring setup requirements or production efficiencies, all this while still meeting quality while keeping costs reasonable.

Businesses looking for smaller trial needs can select one of our stock designs with an MOQ of 250 units, customization options become increasingly limited at this volume. Startups and emerging brands can take advantage of our sample program which provides small test batches from 50-100 units at a higher per-unit cost to validate packaging concepts before committing to full production quantities.

Established brands with ongoing needs can take advantage of our flexible warehousing and release programs to produce larger quantities at optimal pricing points while being stored and shipped according to your schedule. This way, inventory management with cost considerations becomes simpler.

Pricing Structure

Understanding our tiered pricing structures enables you to make informed decisions regarding your packaging investment. At wholesale large gift boxes, we believe in keeping things accessible, offering incentives at lower quantities yet rewarding volume sales with reduced rates. Base pricing begins at 2.50-4.00 per unit for standard sizes (10″x10″x5″ to 14″x14″x5″) when ordering 500 units; these costs fall gradually over time until reaching 1.75-3.00 at 2,500 and 1.5-2.25 when placing orders of 10,000+ items. Various factors determine your custom packaging’s final cost point, including size requirements and volume demands. Dimensional requirements determine material consumption; larger boxes require more raw materials. Material choice has an enormous influence on cost; options range from standard 18pt SBS cardboard up to premium 26pt stocks or specialty papers.

Complex printing designs such as multiple colors used and coverage area impact production time and setup requirements for setup requirements and setup requirements, respectively. Special finishing techniques like foil stamping, embossing, or window installation each incur incremental costs depending on complexity or coverage area; orders of 1,000 units offer significant opportunity for savings, with price breaks typically occurring after 2,500, 5,000, and 10,000 units have been produced.

Businesses with ongoing needs can rely on our contract pricing with guaranteed rates for 6-12 month periods to protect from material cost fluctuations while providing predictable budgeting. Our transparent quoting process features breakdowns of every component contributing to your final price ensuring you fully comprehend its worth as an investment in packaging solutions.

Production Timeline

Understanding your production timeline allows for effective planning of product launches and special promotions. On average, large gift box production cycles take 15-25 working days from final design approval through to shipping. Pre-production begins with final artwork preparation, color matching, and die line confirmation – processes that typically require 3 -5 working days of pre-production time. Production Phase The production stage typically spans material preparation, printing, die-cutting, gluing, and finishing operations which take 10-15 working days depending on order complexity and facility load. Quality inspection and packaging preparation add another 2-4 days before goods can be shipped for distribution.

Factors that may extend our timeline may include custom die creation for unique structural designs (5-7 days), specialty finishing techniques like hand-applied elements (3-6 days), or material sourcing for uncommon stocks or sustainable options (possibly adding 5-10 days). We offer expedited production services that can shorten this standard timeline by up to 40% with rush options for standard designs available with 10-15 day turnarounds at additional fees based on order size and complexity.

Recurring orders using familiar designs typically take 12-20 working days due to reduced setup requirements and our regular production milestone updates in our client portal, providing transparency through each stage of manufacturing and enabling you to track the order from the production floor to the shipping dock.

Sample Services

Conducting quality evaluation before full production runs can ensure your final order fulfills your expectations. Our sample service offers multiple ways to verify design, material, and construction quality before proceeding with full runs of production runs. Pre-production sample processes typically commence with digital proofs that display exact dimensions, print layouts, and color specifications for initial approval. As soon as your digital approval has been received, we produce physical white samples (unprinted mock-ups). These white samples showcase your packaging’s structural design, folding mechanisms, size, and feel before being printed with final graphics and artwork. Pre-production samples may be created with actual printing and finishing methods for an in-depth evaluation, although these typically cost between $150-350 depending on complexity. Their development typically takes between 7-12 working days for comprehensive samples with all finishes applied.

Sample evaluation can provide numerous advantages to businesses. They allow us to test actual product fit within the packaging, verify unboxing experience elements, and validate shipping durability through transit testing, as well as obtain stakeholder feedback before full production commitment is made. Furthermore, for businesses wanting to compare multiple options side-by-side we provide sample kits featuring various material weights, finishing techniques, or structural variations to facilitate comparison of options side by side.

Sample request procedures are straightforward, simply reach out to your dedicated account manager with specifications or use our online sample request portal where you can upload design files, specify requirements, and track sample production status. Any sample costs incurred during production quantities will be applied as credits towards final orders.

Quality and Expertise

Material Selection

Outstanding packaging starts with superior materials that combine aesthetic appeal and functional performance. At Wholesale Large Gift Boxes we select materials carefully that balance quality, sustainability, and value. Core structural components typically use rigid paperboard ranging in thickness between 18-30 points to offer stability and protection while simultaneously creating sharp corners and edges. Starting from this base can be enhanced with premium cover stocks such as FSC-certified offset papers, textured specialty sheets, or recycled kraft options for packaging that brings unique personality. We also provide coated stocks featuring pearl, metallic, or soft touch finishes which create an immediate tactile impact when customers interact with your brand.

Each material undergoes stringent durability tests that include crush resistance, tensile strength, and fold endurance in order to guarantee performance throughout its supply chain journey. Our material procurement prioritizes responsible suppliers with transparent chain-of-custody documentation while offering recycled content options ranging from 30-100% post-consumer waste recycling. In addition for brands looking for green solutions, we also provide alternative papers made of cotton fibers or stone papers containing calcium carbonate or materials composed of agricultural waste like wheat straw or bamboo fibers as solutions.

All adhesives used during construction are carefully chosen with consideration given to both bond strength and environmental impacts, with water-based formulations often becoming our default standard across our production facilities. Our dedication to material excellence guarantees your packaging maintains structural integrity while offering customers a memorable brand experience.

Quality Standard

We ensure consistent quality to protect your brand’s reputation. Our quality control covers every stage of production, starting with checking materials like paper, ink, and adhesives for consistency and compliance with safety standards. Pre-production planning sets clear inspection criteria for color, size, and alignment.

During production, automated systems and operator checks monitor quality in real-time. We follow strict sampling protocols to catch any issues early, with additional tests for strength, durability, and color accuracy. Our facilities are ISO 9001 and FSC certified, reflecting our commitment to quality and sustainability. This ensures your packaging looks professional and consistent, reinforcing your brand’s image.

Production Capabilities

Our robust manufacturing infrastructure meets diverse packaging needs with the capacity to adapt to business growth. Spanning over 120,000 square feet, our production facilities include comprehensive capabilities that cover every facet of custom packaging creation – printing department equipment includes six-color offset presses with inline coating units capable of processing 15,000 sheets an hour; digital presses offer similar quality without setup costs for short run productions; while computerized die-cutting machines with positioning accuracy as precise as 0.1mm at speeds up to 7,500 sheets an hour ensure precision and efficiency for conversion equipment ensuring both precision and efficiency!

Special finishing capabilities of Special Finishing Solutions encompass hot foil stamping with multiple feeding stations for complex designs; embossing/debossing with depth controls up to 1mm; window patching for crystal-clear PET installations and specialty gluing systems to complete unique structural designs. We employ in-house structural designers using CAD systems for custom packaging solutions while creating and testing prototypes before full production begins; additionally, color management specialists rely on spectrophotometry-calibrated proof systems to maintain color fidelity across materials and production runs.